American made chainsaw mills

Test Promo

Black Friday Sale! Up to 50% off

- Free shipping on orders over $100

- Exclusive deals on accessories

- Discounts on all Alaskan Chainsaw Mills

Our Products

Why Granberg?

Since our founding in 1954, Granberg International has been dedicated to empowering woodworkers and sawyers worldwide. Known for inventing the Alaskan Chainsaw Mill, we deliver tools designed for precision, reliability, and lasting performance. Whether you're a professional or a weekend DIYer, our products are built to help you bring your vision to life.

Discover Our Story

Top-rated Products

Calendar of Events

Chainsaw Milling Basics Workshop

Chainsaw Milling Webinar

What Our Customers Say

Product REviews

News & Insights

Choosing the Right Chain for Your Chainsaw Mill: A Complete Guide

Choosing the right chain for your chainsaw mill is crucial for optimizing performance and ensuring…

Is a Chainsaw Mill Worth It? Granberg International’s Precision Solution

What is a Chainsaw Mill? Chainsaw milling allows users to transform logs into custom lumber…

Granberg Alaskan® Mill Featured in TimberLine Magazine!

We’re absolutely thrilled to announce that the Granberg Alaskan® Mill was recently featured in TimberLine…

Frequently Asked Questions

What chainsaw engine size do I need for an Alaskan Chainsaw Mill?

The ideal chainsaw depends on your mill size and intended use. For occasional or smaller log milling, a 70cc chainsaw provides adequate power. For regular use with larger logs (over 20″ diameter) or hardwood species, consider 90cc or larger. More displacement means faster cutting, less strain on the engine, and better performance in demanding conditions.Recommended Products:- 24″ Alaskan MKIV Mill (G778-24) – For 50cc+ chainsaws

- 36″ Alaskan MKIV Mill (G778-36) – For 60cc+ chainsaws

- 48″ Alaskan MKIV Mill (G778-48) – For 90cc+ chainsaws

- 60″ Alaskan MKIV Mill (G778-60) – For 120cc+ chainsaws

How do I choose the right bar length for my mill?

In general, the mills are matched to bar length. So a 36” bar and 36” mill go together. However, you lose six inches off a single end bar when you mount the mill, so that particular combination will get you a cutting width of 30”. If you need to cut 36”, you would use a 48” mill and 42” bar.

If using a double ended bar, such as what comes with the “C2/C3” package mills, you can expect to have a cutting width about 4 inches less than the overall mill size (so 32” cutting on a 36” mill)

Recommended Products:

- 36″ Mill Bar & Chain Combo Pack – Comes with Mill, Bar and Chain (30-inch cutting capacity)

- 36″ C2 Complete Package – Everything needed for medium-scale milling (32- inch cutting capacity)

- 48″ C2 Complete Package – Professional-grade large mill setup (44” cutting capacity)

Should I use a different chain for milling?

Yes, use a ripping chain specifically designed for milling operations. Unlike standard crosscut chains that cut across the grain, ripping chains have a more aggressive tooth angle (typically 10° vs 30°) to cut efficiently along the wood grain. This results in smoother cuts, less tear-out, and reduced strain on your equipment.Recommended Products:- Granberg Pre-Cut Ripping Chain – Professionally optimized for chainsaw milling

Can I use any chainsaw brand with an Alaskan Mill?

Most professional-grade chainsaws can be used with Granberg Alaskan Mills. However, ensure your chainsaw has sufficient power and can handle extended operation under load. Different brands of chain saws also take different styles of bar mount, so check the product description in the info section of the product page to make sure your saw is compatible or if it needs an adapter.

Recommended Products:

- Alaskan MKIV Mills 24″-84″ – Fit all chainsaw makes and models

- Complete Alaskan Mill C2/C3 Packages – Include universal bar mount adapters

What other factors affect milling performance?

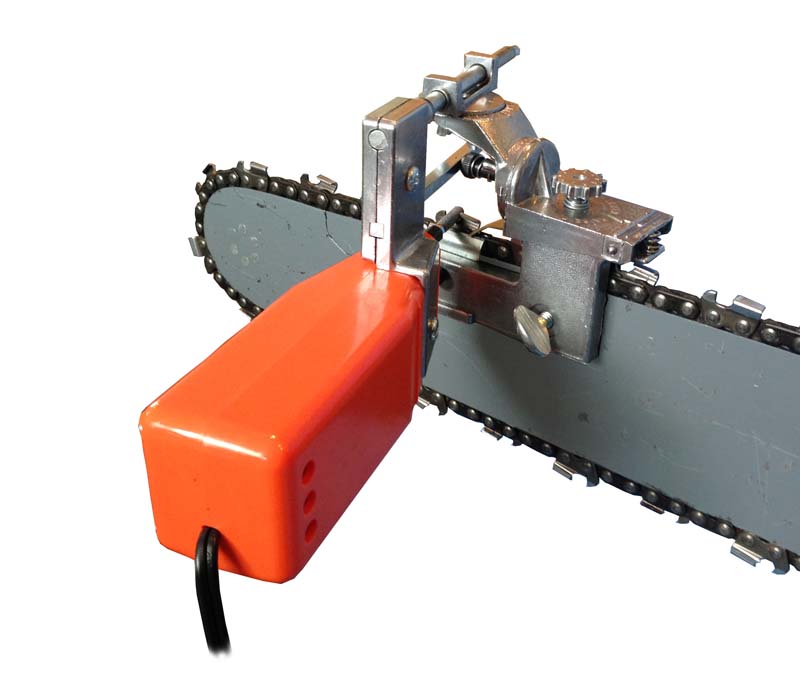

Beyond chainsaw power, consider chain sharpness (critical for clean cuts), proper chain tension, adequate bar oil flow, and your feeding technique. Environmental factors like wood moisture content, temperature, and log species also significantly impact cutting efficiency and finish quality.Recommended Products:- G1012XT Precision Grinder – 12V portable chain sharpener for optimal performance

- G801A Auxiliary Oiler Kit – Enhanced lubrication for bars over 42″

How do I maintain my equipment for milling?

Regular maintenance is essential for safe, efficient milling. Keep chains sharp, maintain proper chain tension, ensure adequate lubrication, clean air filters frequently, and inspect the mill’s rails for straightness. Replace worn components promptly to maintain cut quality and safety.Recommended Products:- G1012XT Precision Grinder – Professional chain sharpening system

- G801A Auxiliary Oiler Kit – Extends bar and chain life through superior lubrication

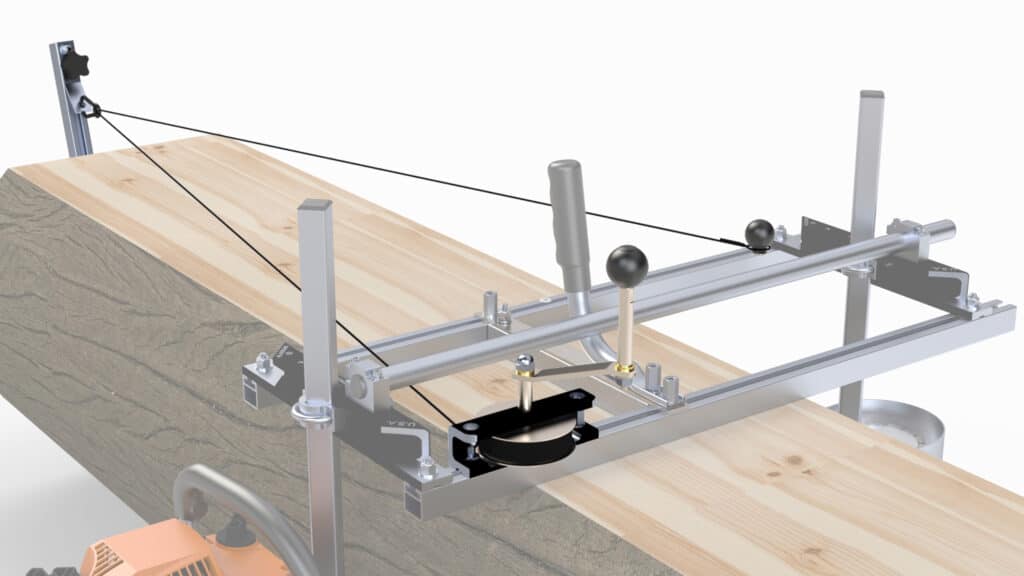

How do I make that crucial first cut on a log?

The first cut establishes your reference surface for all subsequent cuts. A level, straight first cut is essential for quality lumber. Use a guide system to ensure accuracy and prevent the mill from binding or producing uneven slabs.Recommended Products:- G1010 EZ-Rail System (10ft) – Aircraft-grade aluminum rails for perfect first cuts

- G1085 EZ-Rail System (5ft) – Compact version for smaller projects

- G850 Slabbing Rail Bracket Set – Budget-friendly option using customer-provided 2x4s

Complete Starter Solutions:- Slabmaster Bundle – Ultimate 60″ package with mill, EZ-rails, winch, oiler, and grinder

- Backcountry Package 36″ – Complete setup for existing chainsaw owners

Be the first to know

- Early Access to New Products

- First to know about Promotions

- Fun Tips and Tricks